Ningbo Zhengguang Resin Co., Ltd. is wholly-owned production Base of Zhejiang Zhengguang Industrial Co., Ltd. “Zhengguang” is one of the most influential Chinese ion exchange resin manufacture and application company. It was found in October 1969 and has more than 43 years experiences in Ion exchange resin research, development and manufacture history. Zhengguang is also the vice chairman of the China Ion Exchange Resin Committee and a member of WQA.

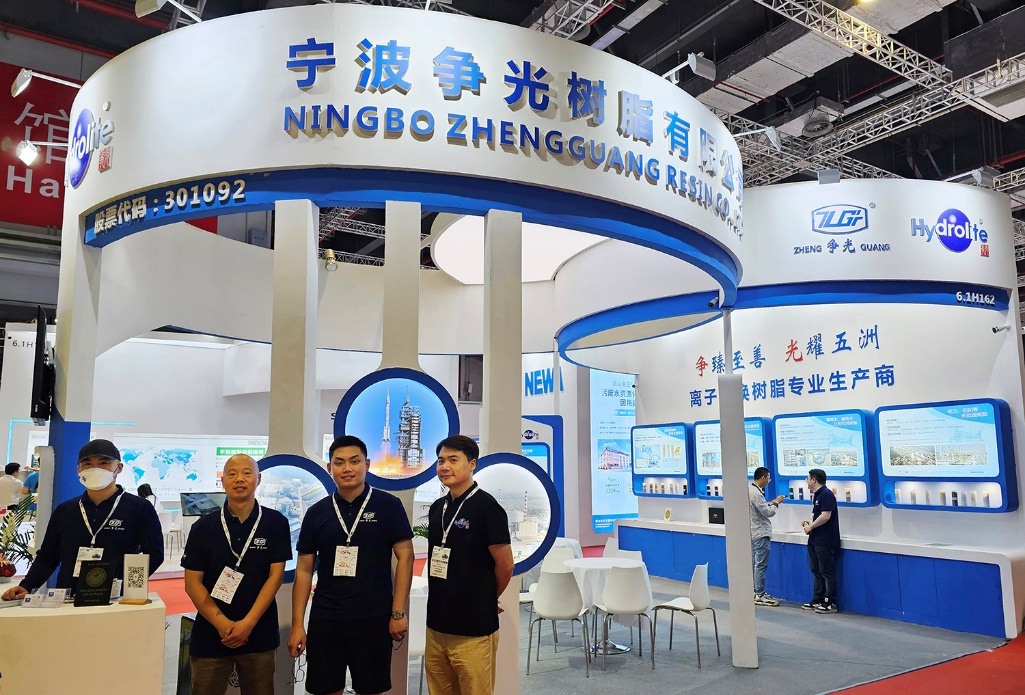

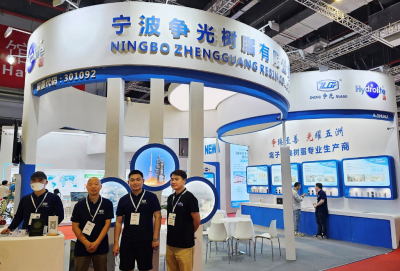

From April 22ed to 24th, Zhengguang was invited to participate in the Water Treatment Exhibition (WQA), one of the most prestigious events in the field of water treatment technology. At the event, our company showcased a series of innovative resins and technical application solutions for water treatment, providing important technical support for solving global water treatment problems and playing a positive role in promoting the innovation and development of water quality treatment technology.

.png)

As a leader in the ion exchange and adsorption resin industry, "Zhengguang" is one of the earliest resin manufacturers in China to join the "International Water Quality Association (WQA)" organization. Some of its products have been certified by WQA, FDA and NSF, and have obtained certificates from WQA, FDA and NSF. Zhengguang resins are widely used in industrial water treatment, high-quality drinking water treatment, industrial pure water and electronic-grade ultrapure water preparation, wastewater treatment and other fields. The products are sold to countries and regions such as the United States, Russia, the European Union, Africa and Southeast Asia, and have a large number of applications worldwide.

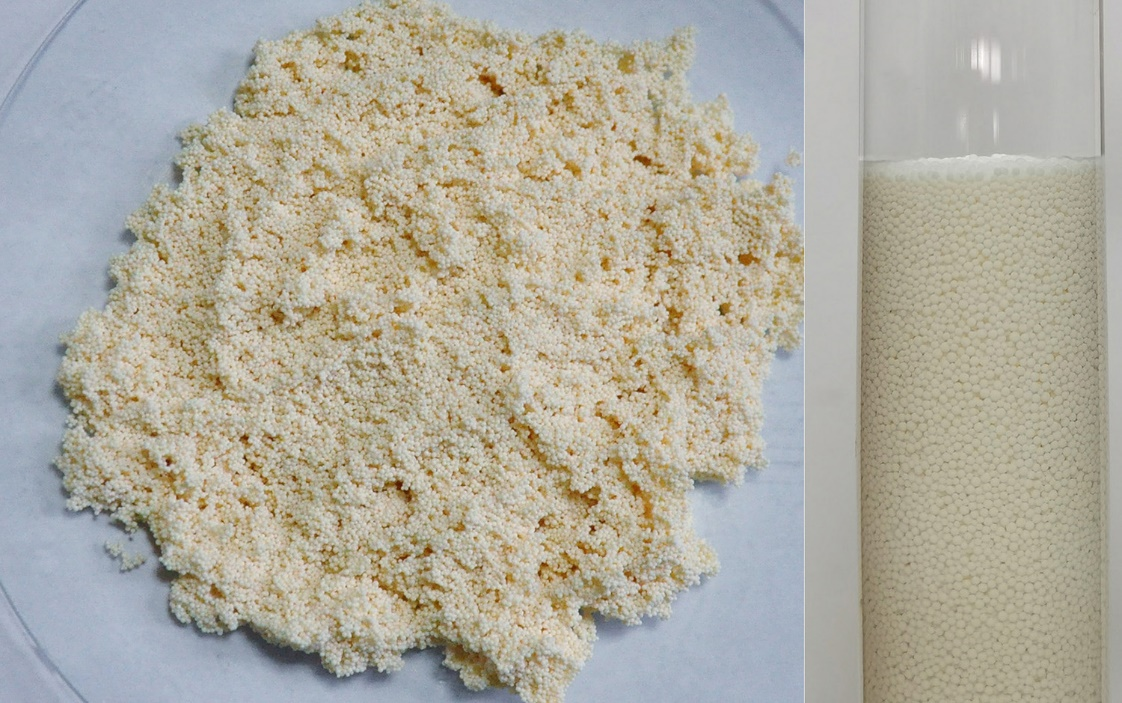

Chromatographic medium is the core material for separation and purification, widely used in the separation and purification of vaccines, antibodies, recombinant proteins, blood products, diagnostic reagents and other biological molecules, with high resolution, high recovery rate, good biocompatibility, easy to scale up, easy to automate operation and other characteristics, to meet the requirements of modern biopharmaceutical, food purification of high standards.

"Zhengguang" is specialized in the accurate preparation and application process development of upstream and downstream nano microspheres in biomedicine, and carries out cutting-edge technology research in life science. With a core R & D team with rich technical experience in the development of medium base spheres and functionalization, we have developed four types of chromatographic fillers: polystyrene/divinylphenyl (PS-DVB), polymethacrylate matrix (PMMA), agarose matrix and glucan matrix, and can provide a variety of chromatographic columns.

The company has a modern production line of chromatographic media and a first-class application evaluation laboratory, with accurate preparation technology, surface functionalization technology and large-scale production capacity. The company is committed to becoming one of the world's leading suppliers of chromatographic separation and purification solutions in the field of life science.

Zhengguang Hydrolite SP series high flow rate and high-resolution polymer ion exchange medium

|

Product name |

Product number |

Gauge grid |

|

Hydrolite SPA308 A |

PS0003-0308 |

Available in 25ml, 50ml, 100ml, 500ml, 1L, 5L, 10L standard packages |

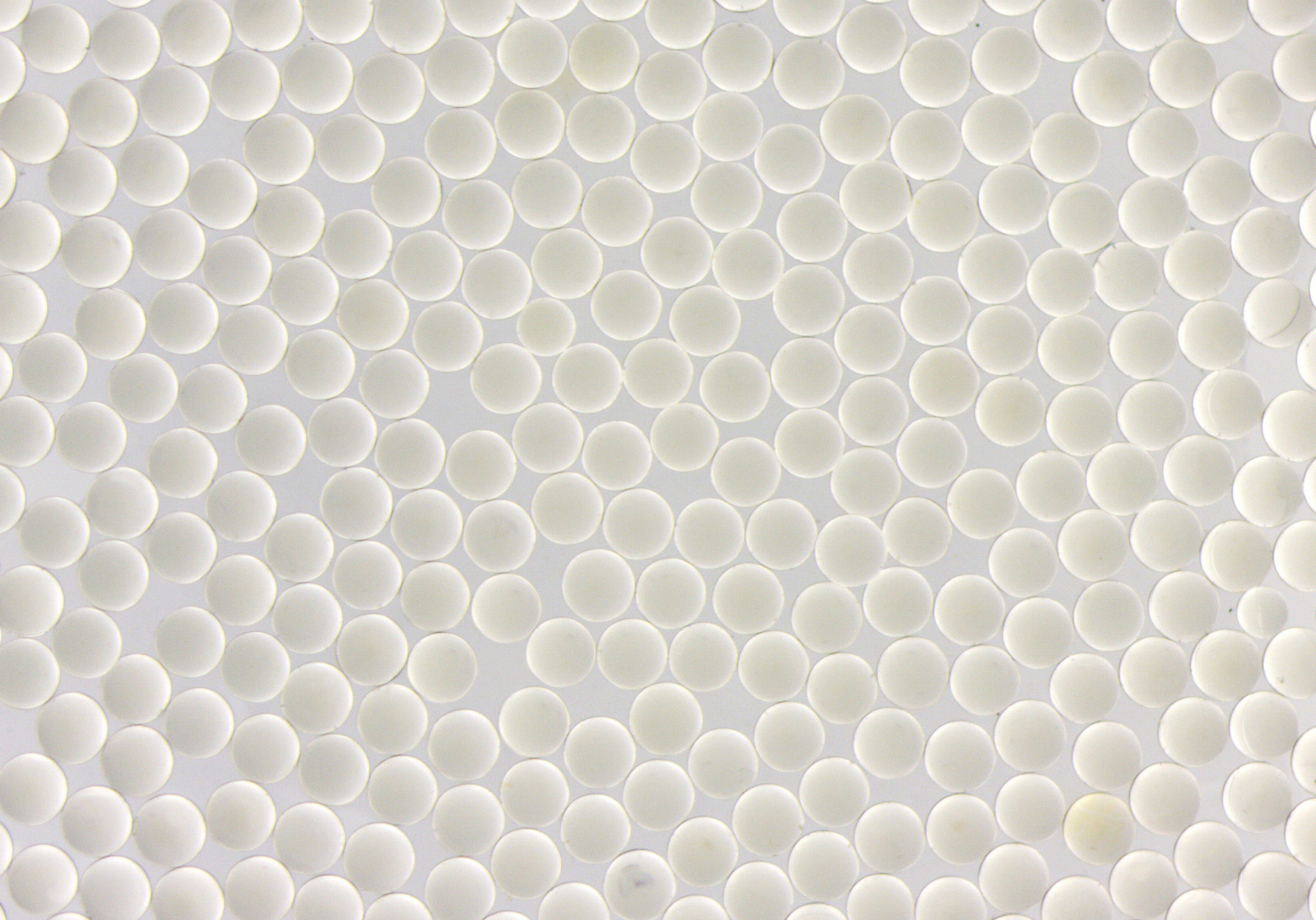

The structure material of the resin separated by ion exchange chromatography is styrene - divinylbenzene, which is prepared by special suspension polymerization process and standardized, and has good chemical and physical stability. Easy loading column, the target component diffusion resistance is small, the product quality is stable.

Therefore, Hydrolite SP series ion exchange chromatography separation resin can not only meet the small process development of fine chemical products such as food and drugs in the laboratory, but also make the process more easily scaled up. The resin with different crosslinking degree has different water content, volume exchange capacity and material diffusion resistance. Such a wide product range enrichis customers' trial choices, and can optimize the appropriate chromatographic separation resin for specific applications.

Hydrolite SPA308A is a strong base anion exchange chromatography medium in the Hydrolite SP series, with quaternary ammonium (Q) strong anion exchange group, particle size 75-150 micron (100-200 mesh), high chemical stability, can perform in place cleaning (CIP) and disinfection processes, It can be used for purification and preparation of small molecules of different scales.

Hydrolite SPA308A application scenario

1.It is used to determine trace levels of rhodium and platinum in environmental biological samples;

2.A strong basic (Type I) anion exchange resin for fine chemicals that meets FDA Food additive regulations;

3.Isolation of inositol phosphate (IP) from myo-[3H] inositol;

4.Isolation of radionuclides;

5.For separating low molecular weight compounds, such as inorganic ions, organic acids, nucleic acids, or carbohydrates;

6.Low crosslinking is used for adsorption and fractionation of relatively high molecular weight substances such as peptides, ribonucleic and deoxyribonucleic acids, and uranium. High crosslinking is used for adsorption, exchange, and separation of low molecular weight inorganic anions, and for applications such as cyclic nucleotide assays and fractional separation of organic acids.

Work hard and keep going. Zhengguang chromatographic medium products fully cover the different stages and application scenarios of upstream and downstream purification, and the performance indicators of products have reached the international advanced level. It provides a strong technical support for the biopharmaceutical field in China, and builds an internationally competitive biopharmaceutical innovation ecosystem.

The structure material of the resin separated by ion exchange chromatography is styrene - divinylbenzene, which is prepared by special suspension polymerization process and standardized, and has good chemical and physical stability. Easy loading column, the target component diffusion resistance is small, the product quality is stable.

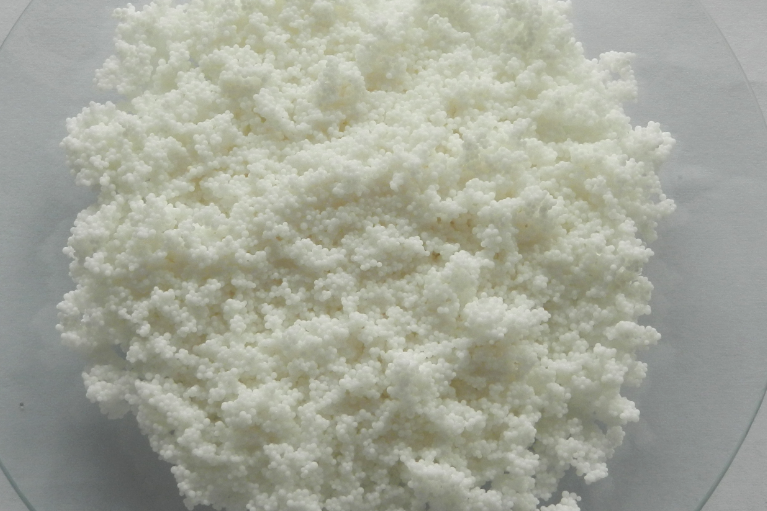

The resin used in the high-end field is known as the pearl in the crown of modern industry, and is an indispensable strategic new material for the high-quality development of the country. It is widely used in the "high precision" emerging science and technology industry, with broad market prospects. A few days ago, the fine processing production line of resin with an annual output of 15,000 tons in the high-end field of Zhengguang was officially completed and put into operation in Ningbo Hydrolite Liquid Separation Technology Co., LTD. The product process is mature, the performance is excellent, and the quality has reached the international advanced level.

Ningbo Hydrolite Liquid Separation Technology Co., Ltd. is a scientific and technological enterprise established in October 2016, covering an area of 61 mu, located in the national chemical park Ningbo Petrochemical economic and technological development zone, has built resin processing center, technology application research and development center, intelligent three-dimensional warehouse, is one of the important production bases under Zhengguang Share.

Resin fine processing center

The company's fine processing center relies on strong research and development strength, mainly dealing with food, drinking water, nuclear power, electronic semiconductor, new energy and other high-end fields of resin. Adopting a number of industry-leading resin finishing automatic production lines, strengthen the application of intelligent and digital manufacturing technology, carry out production standardization and data management, and have the large-scale production capacity of resin in high-end fields.

The company achieves the ultimate quality with high standards, and the resin achieves high purity through high-precision post-processing. Such as used in the production of semiconductor integrated circuit, display, hard disk, CD-ROM and other electronics industry in the manufacture of high purity water, running water resistivity of 18.2 mω.cm above, running water all ion leakage is very low, with excellent dynamic performance, mechanical strength and chemical stability, to meet the customer in the use of the index requirements.

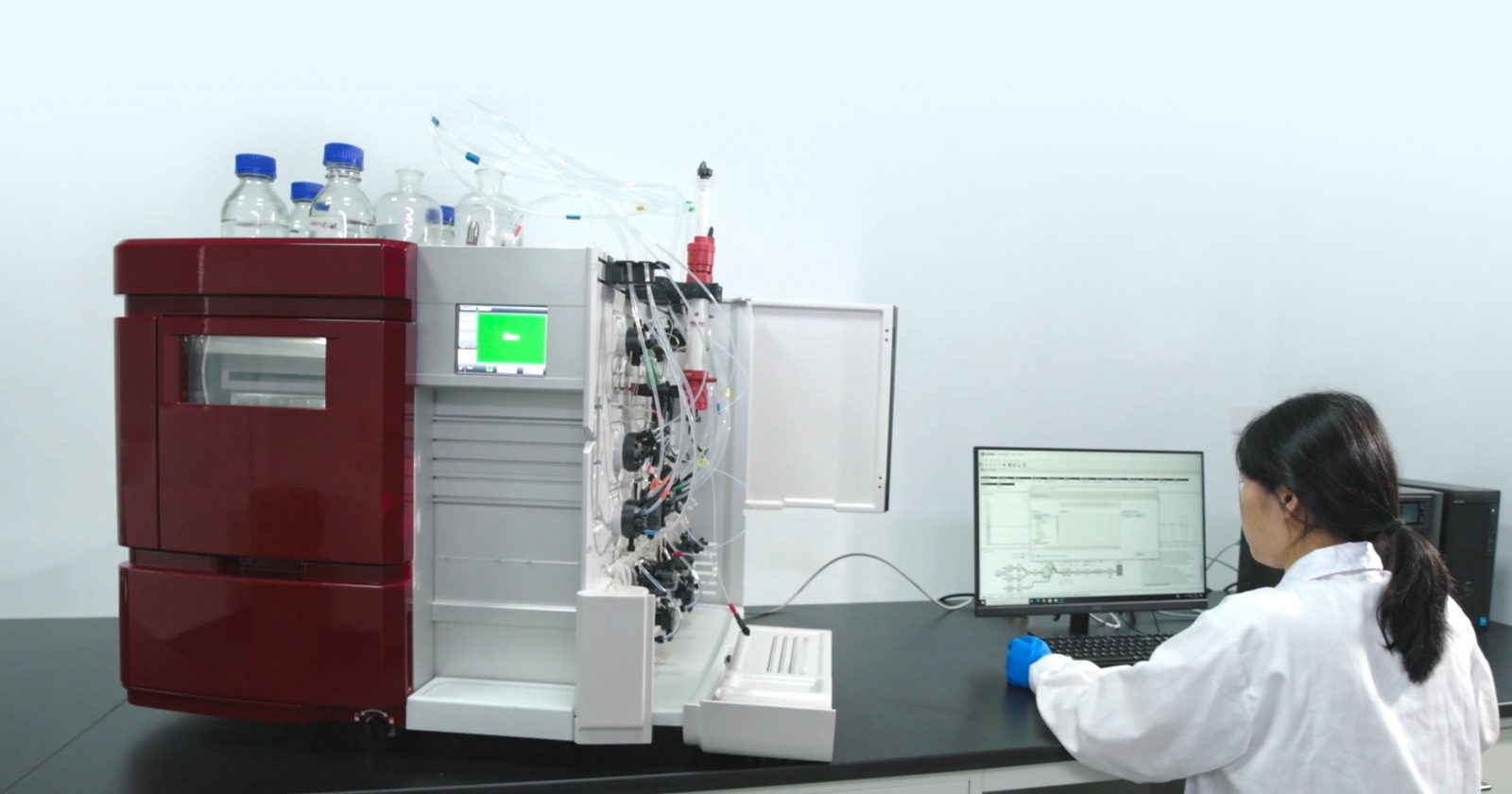

R&D center

Technology Application Research and Development Center is one of the largest resin application laboratories in the domestic industry, with resin application performance test, simulation test, application performance research, application technology research and development of many different functions of the laboratory. A variety of professional experimental equipment is complete, by the professional application team with decades of experience in resin application to cooperate with customers to solve various difficult problems in the use of resin, is committed to providing customers with more scientific and effective resin application solutions.

Intelligent warehouse

The company has the industry's leading intelligent three-dimensional warehouse to meet the storage requirements of food grade, pharmaceutical grade, nuclear grade and other resins, while using sensors and automation equipment to optimize the retrieval and storage of goods, including WMS (warehouse management system) and ERP system to share key data, such as order information, goods flow status, etc. To realize the seamless connection of information and data, reduce errors and repeated input, effectively use space, and improve logistics efficiency, to provide customers with high quality, fast logistics support, improve the quality of modern logistics services.

Deep cultivation of the main industry, innovation leading. "Zhengguang" based on the domestic market, focus on the global layout, seize market opportunities, with industry-leading resin manufacturing technology advantages, focus on doing creative products, cultivate the internationally competitive high-end resin application market, and boost China's advanced manufacturing industry to a new level.

From November 6th to 9th, 2023, “Zhengguang” received continuous praise on the Aquatech Amsterdam 2023 which held at the RAI Exhibition Center, sharing and negotiating with many customers and experts from all over the world, deepened cooperation, and shared resin application experience.

From November 6th to 9th, 2023, “Zhengguang” received continuous praise on the Aquatech Amsterdam 2023 which held at the RAI Exhibition Center, sharing and negotiating with many customers and experts from all over the world, deepened cooperation, and shared resin application experience.

As a leading enterprise in the ion exchange and adsorption resin industry, “Zhenguang” plays an important role in the treatment of boiler supply water and condensate water, the primary and secondary circuit water treatment of nuclear power plants, the preparation of industrial pure water and electronic grade ultra-pure water, food and drinking water and many other fields, and its products are exported to the United States, Russia, the European Union, Africa and Southeast Asia and other countries and regions. It enjoys a high reputation in the international market. At the meeting, the company brought high-quality resin products and innovative water treatment solutions to global users to meet the needs of users for softened water and pure water.

On the morning of September 20, the torch relay ceremony of the 19th Asian Games in Hangzhou was held. Huimin Xiu, technical director and senior engineer of Zhejiang Zhengguang Industrial Co., Ltd. was invited to serve as the 76th torch bearer and relay the torch relay ceremony. She said that this is a supreme honor, but also a heavy mission and responsibility! At that moment, my heart was full of mixed feelings. I felt happy and proud that the 19th Asian Games was held in Hangzhou.

Hangzhou Asian Games torch bearer introduction – Huimin Xiu

Huimin Xiu won the Zhejiang provincial model worker in 2014, is the first female "craftsman" in Yuhang, she is known as the "sonorous rose" in the laboratory, and leads the technical team of Zhengguang Company to focus on the research and development of silver potassium resin, oxygen removal resin, and organic cleaning agent application research and development, nitrate removal application research and development, resin for waste gas treatment, acid recovery and other projects. Published more than 20 papers related to ion exchange resin, and according to the application test results, timely sort out the application data materials of the company's products, so that the company's products have been applied and promoted in many fields, providing customers with a more scientific and more environmentally friendly resin application program, and creating huge social benefits.

Zhengguang adhere to the main business, strengthen industry, actively practice social responsibility, participate in the construction of beautiful Hangzhou, and vigorously promote the spirit of model workers, so that the spirit of craftsmen passed on from generation to generation, and set up "the power of example" for the society.

On August 4-6, the 11th International Exhibition of Biological Fermentation Products and Technology Equipment was held at the Shanghai New International Expo Center. This is a highly anticipated event in the biological fermentation industry in China. As the main exhibitor, Zhengguang conducts technical exchanges with customers on-site.

Fermentation can be used to produce various food additives such as tartaric acid, citric acid, lactic acid, glutamic acid, serine, etc. Ion exchange resins and macroporous adsorption resins have exchange and adsorption characteristics, making them good medium for extraction and separation.

Zhengguang D314FD, J-18, D630, and D315 are all acrylic based macroporous weakly basic anion exchange resins. Due to their specific pore structure and active groups, as acrylic based resins, they have advantages such as high exchange capacity, fast exchange rate, high resolution, and strong anti-pollution ability. They have good adsorption properties for aldehydes in both aqueous and non-aqueous solutions. Mainly used for removing anions such as chloride and sulfate in the production of organic acids such as tartaric acid, citric acid, lactic acid, succinic acid, etc.

Zhengguang C108-L, 001 × 7FD and D001 are food grade specialized strong acidic styrene based cation exchange resins that have been disinfected and sterilized through special processes. Especially suitable for the extraction and desalination of food fermentation industries such as starch sugar, tartaric acid, beer, sorbitol, xylitol, amino acids, citric acid, and lactic acid.

J-18

C108-L

Zhengguang SD300, SD720, SD750, SD730 and other macroporous adsorption resins are suitable for decolorization and impurity removal of fermentation broth. They have advantages such as high decolorization efficiency, large adsorption capacity, high elution rate, and good mechanical strength, and can replace activated carbon for decolorization of feed liquid. The regeneration process is simple and reduces operating costs.

SD730

Zhengguang SPC106H, SPC106K, SPC106Na, SPC106Ca chromatography cation resin, and SPA412 chromatography anion resin can be used for the separation of various similar substances. They have the advantages of high separation purity, high yield, low water consumption, good mechanical strength, good permeability resistance, and superior performance.

The pace of upgrading and increasing production capacity in China's biological fermentation industry is constantly accelerating, and ion exchange and adsorption resins will have a wider application in the fermentation field. Zhengguang will continue to focus on its main business, closely focus on customers’ needs, enhance the company's technological advantages, bring higher quality products and more professional services, and create value for customers.

Water is the source of life and the driving force of ecological civilization construction. During June 5th to 7th, Zhengguang was invited to participate in the “15th Aquatech Shanghai” Water Treatment Exhibition held in Shanghai National Convention and Exhibition Center. In the three days exhibition, our whole house water purification series resins and innovative water treatment technology solutions, aroused great interest of domestic and foreign customers.

Zhengguang is one of the earliest domestic manufacturers for drinking water treatment resin exported overseas, and has decades of technical application experience in serving domestic and foreign customers. We provide drinking water treatment resins to well-known international customers in the market and establish long-term strategic partnerships with these customers.

The high purity of the drinking water treatment resins, which mainly used in the production process of various people's eating or drinking products, to ensure that the products produced meet the requirements of non-toxic and harmless, and do not cause any acute, subacute or chronic harm to human health. The resin adopts a new production process, after strict food-grade process treatment, to meet the GB/T 17219-2001 "Drinking water transmission and distribution equipment and protective materials Hygiene and safety Code", part of the drinking water treatment resins passed the NSF and WQA certification.

ZG C108DQ

DQ series drinking water treatment resins includes: ZG C107DQ, ZG C108DQ, ZG C110DQ, ZG C108FMDQ and other gel type strong acidic cationic resins, with the advantages of fast exchange speed, high mechanical strength, used in water dispenser, coffee machine, high-end aquaculture, flower planting water softening treatment, Can also be used for domestic water heaters, shower equipment, dishwashers and other water softening treatment. In household use, the same regeneration effect is achieved by adding less salt, which improves the utilization efficiency of the resin.

ZG F860

ZG D890, ZG D893, ZG A891, ZG F860, ZG S820, ZG D870B and other macroporous food grade drinking water treatment resins, each resin has a special functional group, can be targeted to remove toxic and harmful substances in drinking water, such as nitrate, phosphate, perchlorate, fluorine, arsenic, boron and so on.

In order to meet the high-quality water needs for thousands of families, purify the water environment of families and communities, improve the healthy water life experience of residents, and expand more drinking water application scenarios, Zhengguang will continue to develop innovative home softening resins, and continue to care for your family's healthy water life...

During March 28th to 30th, "Zhengguang" participate in the 2023 China International Clean Energy Expo. which held in Beijing China International Exhibition Center, bring the company's most cutting-edge technologies and innovative products in the field of new energy, meeting industry partners, technology exchanges and discussions.

Currently, high-tech resin has achieved large-scale application in new energy materials, chips, nuclear power and other fields, and has become a key material for modern industrial production. New lithium batteries and new energy are related to the future of mankind and the national development strategy of "carbon neutrality".

During the exhibition, Zhengguang exhibited the nickel, cobalt and manganese ternary precursor resin applied in the field of new energy, lithium carbonate production industry resin, lithium battery recovery industry resin and polysilicon production resin, and introduced to customers Zhengguang ZG LR328 aluminum lithium adsorbent for extracting lithium from brine. Through lithium ion imprinting technology, the polymer has memory effect on the structure of lithium. The pore structure of the adsorbent has high selectivity for Li+, which can selectively adsorb Li+ in the brine. Other cations with larger molecular weight cannot enter, and the selectivity for lithium is still very high when the ratio of magnesium-lithium is as high as 200∶1. Use hot water to regenerate, no other impurities produced. ZG LR328 aluminum polymer has good mechanical strength, stable physical and chemical properties, 100 times adsorption/desorption dissolution loss rate is less than 0.5%, and stable performance.

In addition to impurity refining, Zhengguang D870B boron removal resin, in 12% magnesium chloride or lithium chloride generally contains about 100ppm of boron, through the resin treatment will reduce the amount of boron to below 1 ppm. D851/D860 calcium and magnesium removal resins, ZGSO107 polymerization type oil removal resin, SD300 adsorption type oil removal resin, FS821 fluorine, silicon, phosphorus, arsenic adsorption resin and so on have good selectivity, excellent adsorption and elusion performance, quality has been tested by the market.

At the same time, the company has the ability of application technical support, separation device engineering design and general contractor, system installation and debugging and other professional services.

Company focuses on the innovation and development of ion exchange and adsorption materials, always adhere to the customer demands oriented, while maintaining the stable development of the original business, continue to explore more applications and scenarios in emerging industries, and constantly enhance the core competitiveness of the company, with better quality products and professional services to win the market!

The 4th National Symposium on Organic Porous Materials, sponsored by Huazhong University of Science and Technology, Wuhan Institute of Technology and Wuhan University, was held in Wuhan from November 4 to 8, 2021. The biennial national symposium has become one of the important academic conferences in the field of organic porous materials in China.

Zhejiang Zhengguang Industrial Co., LTD., chairman of Mr. Jianhua Shen attended and spoke at the meeting in for the introduction and application of macroporous adsorption resin keynote speech, on the characteristics of macroporous adsorption resin, the emphasis on the aspects such as function, illustrates the broad application prospect, macroporous adsorption resin obtained the forum guests warm response, the scene applause continuously. This has greatly promoted the in-depth exchanges among domestic counterparts in the field of organic porous materials, which is conducive to further expanding academic influence, strengthening research strength, focusing on scientific issues and serving national strategies.

The rapid development of global economy has brought huge consumption of energy. Due to the non-renewable nature of traditional energy sources such as oil, coal and natural gas, human beings are facing great challenges in energy sources and consumption, and the situation will become more and more severe. The solutions are as follows :(1) improve scientific and technological progress, develop new production technology and reduce production energy consumption; (2) Develop new energy sources, such as solar energy, wind energy, hydrogen energy, tidal energy and biomass energy, so as to diversify the available energy sources and reduce dependence on oil, coal and natural gas.

As a kind of clean energy, solar energy occupies an important position in the new energy category because of its "inexhaustible and inexhaustible" characteristic. Polysilicon is the most important material for solar cells. In recent 3~5 years, polysilicon industry has developed rapidly in the world, especially in China. Existing domestic and international mainstream technology, solar energy polysilicon mainly adopts improved Siemens method, silane method, the improved Siemens method accounted for about 80% of the chemical hydrogen silicon required for the production of polysilicon theory consumption ~ 5 t/t, but because of the reduction reaction selectivity is not high, equipment design is reasonable, the craft is not perfect, and many other factors, the actual consumption is much higher than the theoretical value, At the beginning of the operation of polysilicon production unit, the single consumption of trichloro silicon reached more than 20t/t. In recent years, with the continuous progress of technology, the single consumption has gradually decreased to 8-10t /t. It is estimated that the capacity of polysilicon projects already built and under construction in China will reach tens of thousands of tons per year. In this way, it is bound to drive a large demand for trichlorosilane. As the most important raw material in the process of polysilicon production, trichloro silicon in China from the real large-scale industrial production started to the present, although it is only a few years, but the development speed is amazing. From the initial period of ~ 4kT /a in 2004, to 300~ 400kT /a in 2009.

The modified Siemens process and silane disproportionation process are the process of purifying and separating the material and then reducing or decompactifying it. In the process of purification and separation, impurity boron is difficult to remove and easy to enrich in the system, which has a great impact on product quality. In addition, during the production process, the system will produce a certain amount of dichlorodihydrosilicon, which belongs to the class A hazard source and is easy to corrode the system equipment pipeline. How to effectively use it is a major problem for polysilicon manufacturers. Macroporous adsorption resins for boron removal and catalytic resins for disdisproportionation of dichlorodihydrosilicon have been developed and applied in polysilicon production.

In polysilicon production, boron and phosphorus in raw materials mainly exist in the form of boron trichloride and phosphorus trichloride, which affect the product quality. Boron, phosphorus removal can be used in polysilicon has been of boron or phosphorus chelating resin with high selectivity, the functional groups on the chelating resin with boron or phosphorus form stable ligand, under the condition of reasonable design process, which can realize the boron or phosphorus content in the liquid chemical hydrogen silicon reduced to 5 parts per the following, from thousands of parts per so as to achieve the goal of boron, phosphorus removal. Polysilicon raw material can provide high quality and stable raw material for distillation section by removing boron and phosphorus by chelating resin, which can reduce the load of distillation section, improve the yield and reduce the energy consumption of the product.

Dichloro dihydrogen silicon boiling point only 8.3 ℃, 58 ℃, spontaneous combustion stability of strong corrosive gases, white smoke produced in the air, in the flame, high fever, the combustion or explosion happens, not easy to spot long-term storage, so two chlorine two recycling and utilization of hydrogen silicon can not only effectively eliminate the safety hidden trouble, but also to a certain extent reduce the production cost. The Di disproportionation process, developed and applied by UCC, is an important method for the recovery of dichlorodihydrogen silicon.

Di disproportionation working principle: catalytic resin

Main reaction: SiH2Cl2+ SiCl4 → 2SiHCl3

Side reaction: SiH3Cl+ SiCl4 →2SiH2Cl2

2SiH3Cl → SiCl4 + 2SiH2Cl2

Di disproportionation catalysts are mainly cyanide, activated carbon, chloride, heterocyclic, amine or amine salt and amide, supported catalyst, widely used is alkaline macroporous catalytic resin.

Will liquid dichloride dihydrogen silicon and silicon tetrachloride according to certain proportion of mixed in pipeline mixer, mixing after send buffer tank, again through the pump to the disproportionation preheater, after preheating material sent to the catalytic reactions in fixed bed reactor, reaction products after cooler, then send purification system, through the disproportionation reaction, Most of dichlorodihydrosilicon and equal mole of silicon tetrachloride are converted to trichlorodihydrosilicon, effectively recovering dichlorodihydrosilicon and silicon tetrachloride.

In disproportionation reaction, the dichlorodihydrosilicon conversion will increase until reaching a stable value when the feed ratio of dichlorodihydrosilicon increases. As the reaction temperature increases, the conversion rate of dichlorodihydrosilicon will increase, but the excessively high temperature catalyzes the fall off of the active group of the resin and leads to a decline in the conversion rate, thus controlling the temperature change of the reactor, which is generally 80℃. In the process of disdisproportionation reaction, SiH2Cl2, SiCl4, SiHCl3, SiH3Cl and SiH4 are involved. They have a common characteristic. Under the action of appropriate catalyst, the chemical bond between chlorine atom and hydrogen atom and silicon atom can be opened freely, so that the chlorine atom and hydrogen atom surrounding silicon atom can transfer to each other. And transfer the balance after the formation of the mixture depends on the properties of chlorine atoms and the ratio of silicon atoms, as a result, in particular the bed under the pressure of chlorine atoms and the higher the ratio of silicon atoms, dichloro dihydrogen silicon conversion rate is higher, the higher the temperature of the catalyst, the higher activity, open the higher chloride silicone key ability, dichloro dihydrogen silicon conversion rate is higher.

On November 2nd, 2021, Zhejiang Zhengguang Industrial Co., LTD. (stock abbreviation: "Zhengguang Stock", stock code: 301092) was successfully listed on gem of Shenzhen Stock Exchange. Liping district party committee secretary Rugen Chen, Zhejiang industrial Co., Ltd., chairman of Jianhua Shen, vice President of Guosen securities ChuanLi Chen, vice President of China ion exchange resin membrane industry association Weiguo Zhang common listed treasure bell rang, this will be a proud shares took a new starting point, Zhengguang will be more brilliant tomorrow.

Struggle for decades, realize the dream in the present. At this dream realization moment, some of Zhengguang's customers and partners congratulated us and attended the listing ceremony together with shareholders' representatives, for which we express our sincere gratitude.

On the evening of November 1st, the company held A gala dinner in Shenzhen to thank its initial A-share listing. Hangzhou Linping district government leaders, principals of listing guidance institutions, shareholder representatives, some customers and suppliers, industry leaders, industry media guests and friends from all walks of life who care about and support zhengguang Share development gathered together to celebrate the great event.

Don't forget the beginner's mind, the company "to become the international first-class ion exchange and adsorption resin manufacturers" as the goal, constantly improve product quality and brand image, and increase investment in research and development, enhance innovation capacity, optimize the product structure, improve the product's market share and establish its in ion exchange and adsorption resin industry leading position.

We look forward to the success of Zhengguang Shares listed in A-shares. We will rely on the powerful power of the capital market to adhere to the main business, standardize operation, integrity management, continuous innovation, and return the trust and support of the majority of investors and the society with good performance.

TEL:86-571-86372141 86-571-86372390

Technical Service:86-571-86372035