Your location: Home » News

ZG NR D870B

Semiconductor-grade ultra-pure water boron removal resin

In ultrapure water treatment

Reduce the boron concentration to below 5ppt

Water quality is close to absolute purity

Compliant with ATSM and SEMI international advanced standards

Ultrapure water preparation is key to semiconductor manufacturing, and improving yield requires not only advanced production and manufacturing technology, but also advanced ultrapure water process support. Trace amounts of boron in ultrapure water can disrupt semiconductor electrical properties, interfere with process stability and reduce product yield. To meet semiconductor process requirements, the concentration must be controlled at the ppt level (parts per trillion) ion content standard through boron-removing resin adsorption and real-time monitoring.

The International Semiconductor Association (SEMI) recommended in its 2021 guidelines for ultrapure water for semiconductor processes that the boron concentration in ultrapure water should be less than 50ppt after terminal ultrafiltration. Some advanced processes and related industries (e.g., chip upstream raw materials or chemicals required for the process) have higher requirements for boron concentration in ultrapure water.

1. Product Introduction

ZG NR D870B is a highly regenerating, high-purity boron-removing chelating resin with n-methylglucosamine as its active group, which can form a very stable complex with boric acid and is inert to other anions, helping to form stable complexes with borate ions in water. When used in high-purity water terminal electronic-grade mixed beds in the electronics industry, ZG NR D870B can reduce the boron content in water to less than 5ppt under the condition of proper feed water treatment and reasonable water treatment design, ensuring that the terminal water meets the requirements for each ion impurity, B, TOC.

2. Performance advantages

~High selectivity: High selectivity for borate ions

~ High adsorption capacity and high adsorption rate: Reduce boron in ultrapure water to less than 5ppt

~ High purity: Undergone strict post-treatment and regeneration

~Good stability and tolerance: High mechanical strength, good impermeability and good heat resistance

~ Good economic benefits: Excellent adsorption performance and regenerative capacity, reducing energy consumption and costs.

3. Working Curve graph

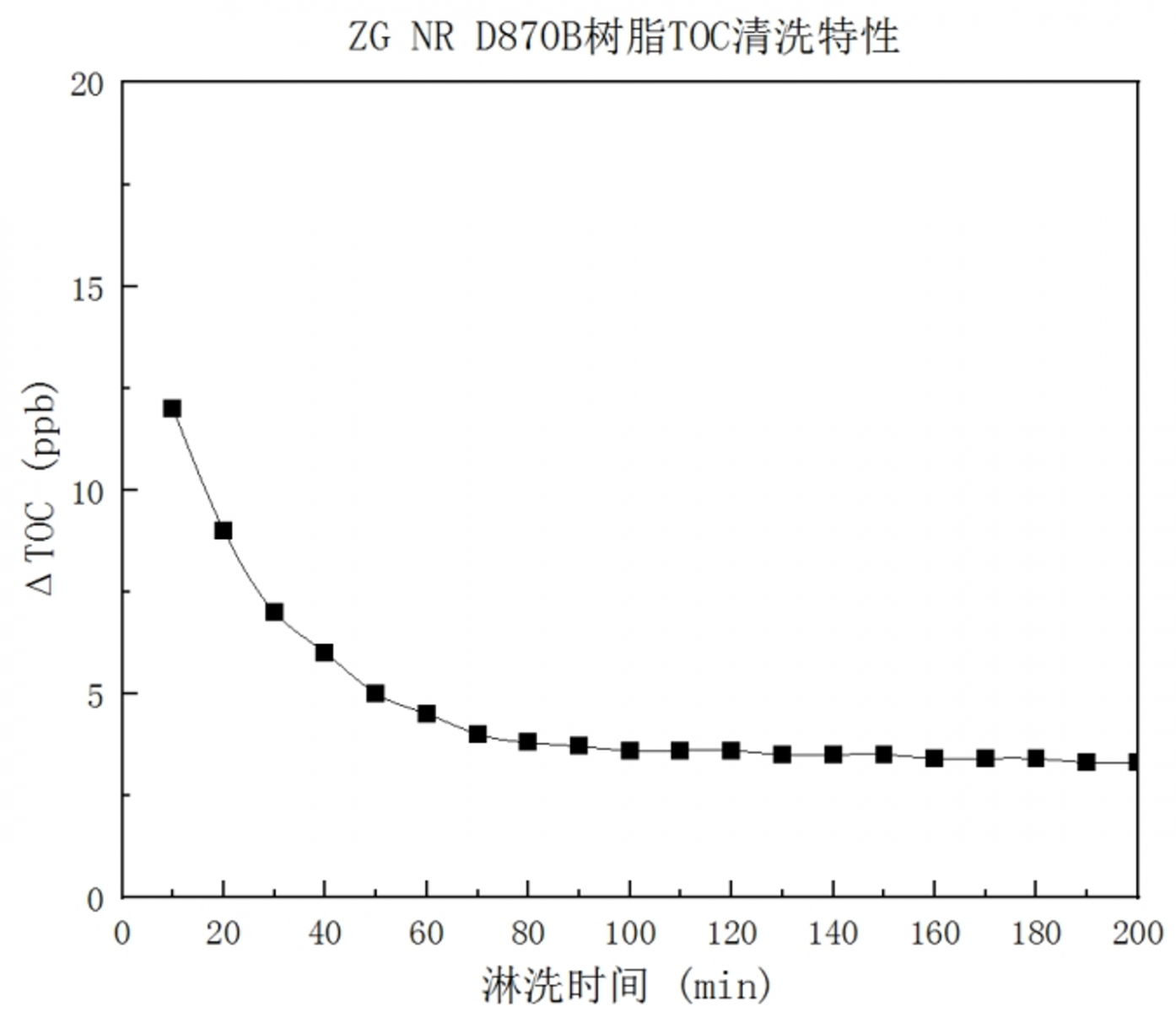

1. Operating effluent TOC variation curve

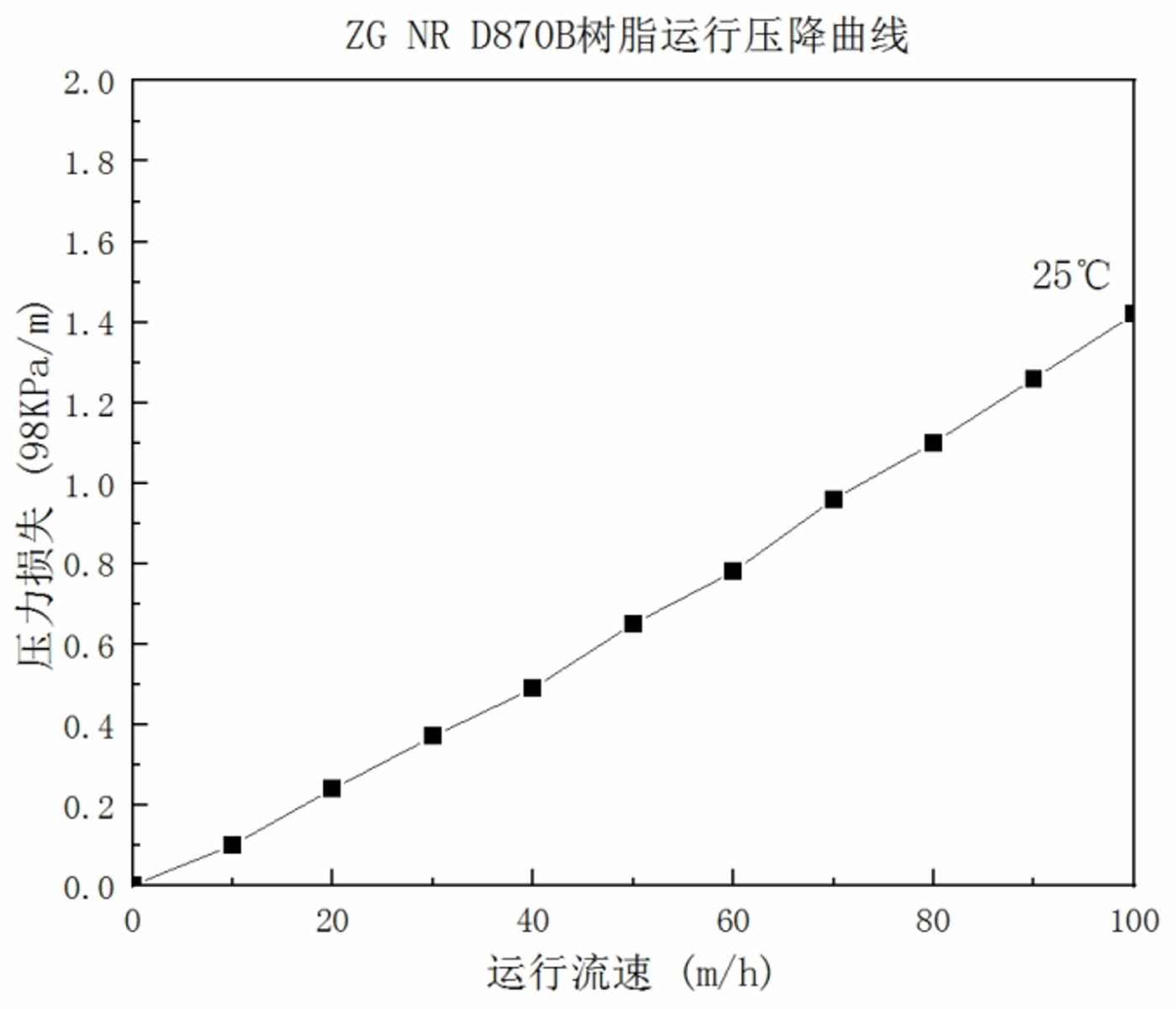

2. Operating pressure drop curve graph

4. Application Cases

Zhengguang ZG NR D870B resin has excellent boron removal performance

Application industries: Electronic semiconductors

|

Influent water quality |

Parameters |

Effluent quality |

Parameters |

|

Resistivity MΩ.cm |

15 |

Resistivity MΩ.cm |

6 |

|

TOC, ppb |

≤3 |

TOC, ppb |

≤1 |

|

B concentration, ppt |

50 ~ 100 |

B concentration, ppt |

3 ~ 4 |

The end-point resistivity of the equipment is greater than 18.2 megohms, the boron concentration is reduced to 3-4 PPT, the water quality meets the ultra-pure water requirements of the semiconductor industry, and also has excellent properties such as high temperature resistance, oxidation resistance and high strength. The overall performance of the product is on par with the international leading level. It will significantly increase China's self-sufficiency rate of electronic-grade ultrapure water and reduce its reliance on imports.

Innovation knows no bounds. From filling domestic gaps to being on par with international standards, "Striving for Glory" contributes to the country's high-tech development by continuously enhancing product quality and technological content to build resin brands with international competitiveness.

Ultrapure water preparation is key to semiconductor manufacturing, and improving yield requires not ...

With the wide application of plant extracts, macroporous adsorption resins have played an important ...

From April 22ed to 24th, Zhengguang was invited to participate in the Water Treatment Exhibition (WQ...

TEL:86-571-86372141 86-571-86372390

Technical Service:86-571-86372035